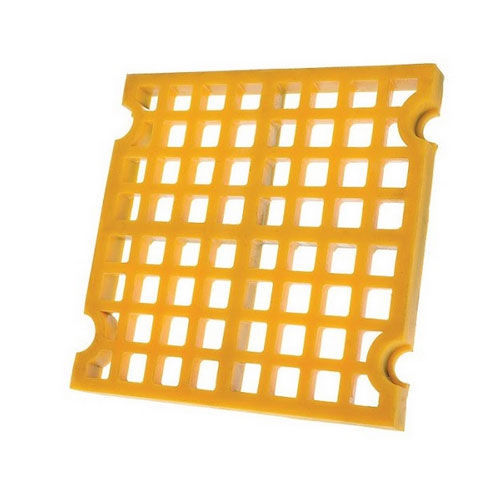

पीयू फ्लिप फ्लॉप स्क्रीन

उत्पाद विवरण:

- उपयोग माध्यमिक तृतीयक और अंतिम स्क्रीनिंग

- टाइप करें

- साइज 610 मिमी x 300 मिमी (24" x 1113/16") 305 मिमी x 305 मिमी (12" x 12")

- शर्त

- प्रॉडक्ट टाइप पीयू फ्लिप फ्लॉप स्क्रीन

- रंग लाल

- अधिक देखने के लिए क्लिक करें

X

पीयू फ्लिप फ्लॉप स्क्रीन मूल्य और मात्रा

- टुकड़ा/टुकड़े

- 50

पीयू फ्लिप फ्लॉप स्क्रीन उत्पाद की विशेषताएं

- 610 मिमी x 300 मिमी (24" x 1113/16") 305 मिमी x 305 मिमी (12" x 12")

- पीयू फ्लिप फ्लॉप स्क्रीन

- माध्यमिक तृतीयक और अंतिम स्क्रीनिंग

- लाल

पीयू फ्लिप फ्लॉप स्क्रीन व्यापार सूचना

- ,

- 5000 प्रति महीने

- 7-10 दिन

उत्पाद वर्णन

We are a leading and trusted manufacturer of PU Flip Flop Screens in India. To ensure superior industrial quality, we use only premium-grade raw materials sourced from reliable and reputed vendors in the market.

Used for:

- Mining Industry

- Steel Plants

- Cement Plants

- Mineral Beneficiation Plants

- Coal Washeries

- Power Plants

Applications:

Secondary Tertiary & Final Screenings

Specification:

- Panel Size: 610mm x 300mm (24" x 1113/16") 305mm x 305mm (12" x 12")

- Aperture Size: 0.35mm x 80mm (1/70" x 31/8")

Durable Polyurethane Construction

Manufactured from premium-grade polyurethane, the PU Flip Flop Screen offers resilience against wear and tear, making it suitable for heavy-duty and high-throughput operations. Its flexible nature reduces the likelihood of screen blinding, thereby enhancing screening efficiency in various industries.

Optimized for Secondary, Tertiary, & Final Screening

Engineered specifically for secondary, tertiary, and final screening, this product ensures reliable particle separation. Its versatility allows it to handle a range of material sizes, supporting optimal performance in mining, quarrying, and industrial applications.

Available in Multiple Sizes & Easy Installation

With available sizes including 610mm x 300mm and 305mm x 305mm, the PU Flip Flop Screen is adaptable for different machine requirements. Designed for straightforward installation and replacement, it minimizes downtime and increases overall operational productivity.

FAQ's of PU Flip Flop Screen:

Q: How is the PU Flip Flop Screen installed in screening equipment?

A: The PU Flip Flop Screen is designed for easy installation and replacement in most standard screening machines. Users can typically fit the screen panels by aligning them into the designated frame or deck with appropriate fasteners, following the manufacturer's installation guide.Q: What applications are most suitable for this PU Flip Flop Screen?

A: This screen is ideal for secondary, tertiary, and final screening stages in various industries such as mining, construction, and industrial processing, where efficient separation and reduced clogging are essential.Q: When should the PU Flip Flop Screen be replaced?

A: The PU Flip Flop Screen should be replaced when you notice significant wear, reduced screening efficiency, or visible damage on the polyurethane surface. Regular inspection will help maintain optimal performance and minimize downtime.Q: Where can I purchase the PU Flip Flop Screen in India?

A: You can acquire the PU Flip Flop Screen from reputable exporters, manufacturers, suppliers, and wholesalers across India who specialize in screening solutions and industrial equipment.Q: What is the process behind manufacturing these screens?

A: These screens are produced using high-quality polyurethane and advanced molding techniques, ensuring precise dimensions and uniform flexibility. The manufacturing process emphasizes durability and resistance to abrasion, contributing to longer operational life.Q: How is the PU Flip Flop Screen beneficial compared to conventional screens?

A: PU Flip Flop Screens offer increased durability, flexibility, and resistance to blinding. Their design enhances screening efficiency, leads to easier maintenance, and supports longevity under demanding conditions.Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

मोबाइल number

Email

पॉलीयुरेथेन स्क्रीन पैनल अन्य उत्पाद

|

HMB ENGINEERING

सर्वाधिकार सुरक्षित.(उपयोग की शर्तें) इन्फोकॉम नेटवर्क प्राइवेट लिमिटेड . द्वारा विकसित एवं प्रबंधित |